BIC Process Design

Understand & Transform

Supercharge your business operations with the most intuitive AI-powered BPM software.

It seems that you come from a German speaking country. Here you can change the language

English

The global setup of the automotive supplier Huf required a lot of flexibility in setting up the process structure as well as multilingual availability of all content in the process portal. The use of BIC Platform provided an effective solution.

As a globally active company in the automotive industry, Huf had to pay particular attention to doing justice to the employees in the different countries when structuring and documenting the process landscape. By mixing decentralized and centralized approaches, the aim was to ensure the broadest possible use and creation of process models on the one hand, and to ensure documentation quality on the other. With BIC Platform, Huf has a multilingual process portal as a central entry point for all process-relevant information. In order to automatically display evidence of the various standard requirements, the company has also fully integrated the process management system into the quality management system - and can quickly and easily demonstrate its high quality during certification procedures.

Huf Hülsbeck & Fürst GmbH & Co. KG

Headquarters: Velbert, Germany

Employees: 7,000+

Industry: Consulting

BIC Platform module in use:

BIC Process Design

With the BIC Platform process portal, all Huf Group employees worldwide can access multilingual versions of all process content. Simple displays, comment functions and intuitive use ensure a high user-friendliness.

Central, multilingual

process portal for all employees

Representation of local

and global processes

Data migration

within shortest time

Complete integration of the

quality management system

The Huf Group is successfully represented in 14 countries around the world with subsidiaries in the area of production and/or development. Due to this worldwide positioning, flexibility in the establishment of the process structure, multilingualism and rapid distribution of process changes were basic requirements for the establishment of the process management system. From the very beginning, there was a need to establish a process structure that would meet the requirements for defining central default processes, but also allow flexibility for local processes. In addition, it had to be possible to map process variants in different ways using an intuitive modeling methodology. In the automotive industry, the quality management system also plays a crucial role. For example, the various Huf companies have received more than 40 different certificates over the years (including ISO/IEC 27001:2005, ISO/TS 16949:2009, ISO 14001:2009 and OHSAS 18001:2007). The company was therefore also looking for a solution that would meet these requirements.

The quality management managers at Huf were aware that the key success factor of the process management initiatives lies not only in the modeling and analysis of the business processes, but above all in the user-friendly communication of the process information throughout the company. Therefore, after an extensive tool evaluation, they decided to switch from the ARIS® platform to the BIC Platform. The change was intended to focus on user acceptance, on the one hand among the modelers, but above all among the users who are supposed to read and live the processes. In a first step, the processes modeled with ARIS® were migrated using an import interface. After the data migration, the modelers were trained, fundamental issues such as the structuring of the process map were examined and changes were made where necessary. The new management system is divided into the classic process categories of management, core and support processes. The value chain is characterized by the process areas of product creation, manufacturing process creation and production and - in line with the defined process hierarchies - is concretized by detailed processes.

With the BIC Platform process portal, process information is made available to all Huf Group employees in multiple languages. The Huf process portal has thus become the central entry point for employees for all process-relevant information. Intuitive display options, personal entry views and the comment function for employees ensure the greatest possible user acceptance. Process changes can be communicated and rolled out quickly and effectively worldwide via the portal. Huf has fully integrated the process management system into the quality management system. This means that evidence of the implementation of the various standard requirements can be automatically displayed in the system. In addition, database-supported evaluations of process interfaces and corresponding process manuals can be generated at any time. These exports can then be made available to various stakeholders such as employees, suppliers, customers and auditors.

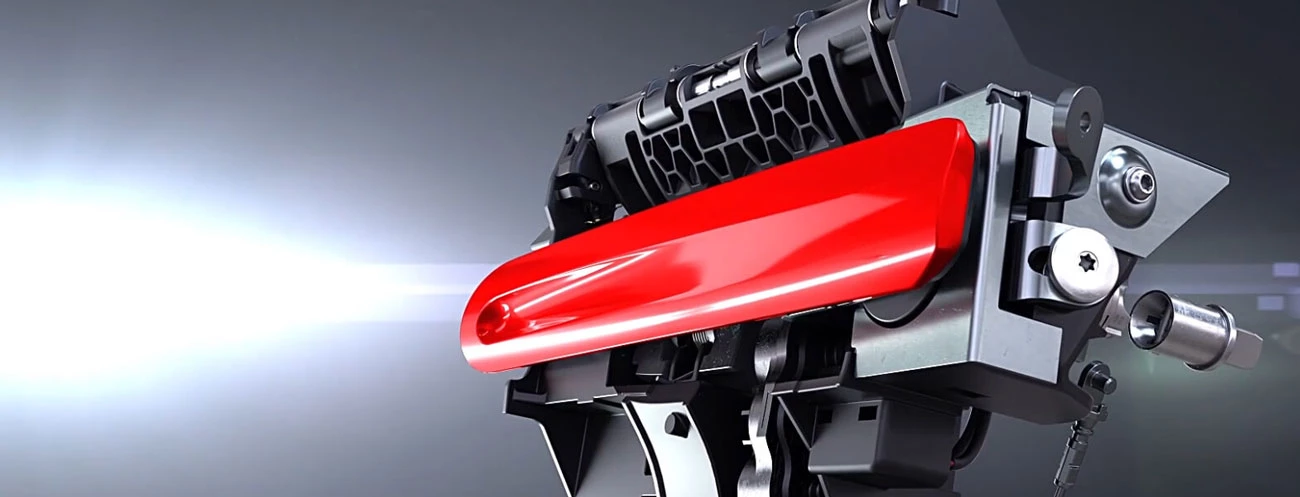

The Huf Group develops and produces mechanical and electronic locking systems as well as vehicle access and authorization systems for the global automotive industry. Founded in 1908 by Ernst Hülsbeck and August Fürst in Velbert, the family-owned company today has locations in Europe, America and Asia. According to a study by the Handelsblatt, Huf is one of the 20 most innovative companies in Germany. In fiscal year 2020, the Huf Group generated sales of around 1 billion euros and employs around 7,800 people worldwide.

Knorr-Bremse:

Professional and intuitive BPM with the BIC Platform

KOSTAL:

Upgrade of Process Management to a world-wide quality management